I am so excited to show this I put this picture here at the top too!!!! YAY for cheese!

Asiago cheese is a firm pressed cheese from Italy. This is made either of cows milk or a mixture of cows & goats milk. Asiago is a brined cheese & has a natural rind. It is aged for one to two years and will be a hard grateable texture called stavecchio. If eaten at three weeks it is known as Asiago Pressato.

Here are my supplies all disinfected & laid on a clean cloth.

I decided to make a double batch...as I read small cheeses do not age well, so I doubled this to have two nice sized cheeses.

Warm the milk to 92 deg. Add the Thermo B powder starter culture & let it set for 5 min. After, it sets stir with an up & down motion.

Warm the milk to 92 deg. Add the Thermo B powder starter culture & let it set for 5 min. After, it sets stir with an up & down motion.

The recipe asked to use a whisk & use an up & down motion to incorporate the culture into the milk.

I cover my cheese to help keep the milk warm. Let this set for 45 min to ripen the milk.

Stir in the rennet diluted in water.

Stir for one minute. I bought animal rennet & LOVE it so much more that the veggie rennet. The animal rennet as soon as you stir it in the milk you notice a change in the properties of the milk. Cover & let set for 1 hour or until the curds make a clean break.

Here the curds made a clean break.

Cut the curd the book says 1/2 inch cubes...but that does not work for me. I cut them at about 1 1/2 inches to 2 inches. Then I made a couple swipes down at an angle. Doing the cheese this way helps the cheese not to be overly dry...to the point that it can not be cut.

Let this set for 5 min undisturbed.

Over low heat, bring the temperature up to 104 deg over a 40 min period, I stirred carefully with a folding motion. This is what it looked like at the beginning of this 40 min time period.

This is what the curds looked like at the end of the 40 minutes.

Here I am stirring for 15 min. to help the curds shrink.

Heat the curd to 118 deg over low heat, stirring to firm up the curds.

This is to show how much the curds have changed. It is now 118 deg.

Cover & let set for 20 min to allow the curds to settle to the bottom.

Ladle off enough whey to expose the curds.

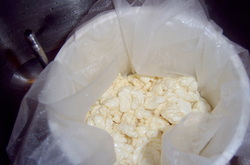

This is the exposed curds....ready to put in the press.

Fill the press with dampened cheese cloth. Put about 1/4 of the curds in each press. If I wanted to at this point they gave us the option of adding whole peppercorns...I do not like to add anything to my cheese so I skipped that step. Then put the follower on top & press with your hands to help the curds fit in the press easier.

Finish filling up the press with the rest of the curd. Place the cheese cloth on top. Press for one hour at 8 pounds.

This is pressing 8 pounds pressure...oh, here is a picture of a present my sister in law gave me....her name is Tilly a cow from Tillamook Cheese Factory. This is a remake of the cow they sold in the 1950s & 1960....it was made in the likeness of a cow they had.

Here is a picture of the clean dishes I just washed...from cheese making...what is missing is the 6 milk jars....as I had to skim the cream off of two of the gallons of milk.

I unwrapped the cheese & am flipping it & redressing it. This will go back in the press for 8 more hours. I then pressed it for 4 hours at 20 pounds pressure...it was to soft so I pressed it for another 4 hours at 30 pounds. It really did not change the

softness....or get firmer. You know, in the past I had trouble making to firm of

a cheese....

softness....or get firmer. You know, in the past I had trouble making to firm of

a cheese....

This looks great! Ready to go in the brine for near 6 hours. I weighed this & it is 2 1/2 pounds. You need to brine this cheese for 2 1/2 hours per pound.

I am SO disappointed! To the fact that my real self came out. I am a quitter or a quitter at heart. I have never quit anything...I PUSH on...but I want to quit! When we had severe wind & were building our home, at one point after working in the severe cold & wind we finished putting on house wrap & lath & taped ever seam & staple, went to town to make cookies for a fun day & came home & every bit of our house wrap was blown off our two story home. I told my husband to BURN the house down & I would not have been sorry! I am glad we didn't burn it down. My husband told me he was not a quitter, I told him I WAS!

Well, with this cheese, after the last cheese Farm House Cheddar & all the cheddars & parmesans to many to count that were inedible (the farmhouse cheddar was edible & yummy, just broken) I wanted to throw my hands up & NEVER make cheese again!

I cried out for help to Ian & Heather & Tiffany & Michelle....I was encouraged to look on the CheeseForum.org, there I looked at the trouble shooting. I found out the brine I used had to high of a ph. I was told that that brine would NEVER go bad. Heather cautioned me to be careful of checking the salt content & I had...but I never thought about it becoming acidic. I had tasted it every time before I used it & it is salty & I thought sweet & smelled fine. I did check the ph level in it & sure enough...what was happening is when I put the cheese in that brine it had a ph shock to the cheese & busted it apart.

I also learned that when you double the batch, using a larger mould you need to add more pressure of the pressing. That was the next error on this Asiago.

To help your cheese curds nit together, if you press them in a covered pot it will help keep it warmer & keep more moisture in giving you a better pressed cheese.

I put this cheese back into the press, the press into a pot, the pot in a sink of 120 deg water & pressed it at 40 pounds pressure for 12 hours.

Well, with this cheese, after the last cheese Farm House Cheddar & all the cheddars & parmesans to many to count that were inedible (the farmhouse cheddar was edible & yummy, just broken) I wanted to throw my hands up & NEVER make cheese again!

I cried out for help to Ian & Heather & Tiffany & Michelle....I was encouraged to look on the CheeseForum.org, there I looked at the trouble shooting. I found out the brine I used had to high of a ph. I was told that that brine would NEVER go bad. Heather cautioned me to be careful of checking the salt content & I had...but I never thought about it becoming acidic. I had tasted it every time before I used it & it is salty & I thought sweet & smelled fine. I did check the ph level in it & sure enough...what was happening is when I put the cheese in that brine it had a ph shock to the cheese & busted it apart.

I also learned that when you double the batch, using a larger mould you need to add more pressure of the pressing. That was the next error on this Asiago.

To help your cheese curds nit together, if you press them in a covered pot it will help keep it warmer & keep more moisture in giving you a better pressed cheese.

I put this cheese back into the press, the press into a pot, the pot in a sink of 120 deg water & pressed it at 40 pounds pressure for 12 hours.

This is what the cheese looks like that I repaired. It still has minor cracking. I made two of these, one in a press with a pressure scale weight & the other in a tommee mould. The tommee mould did not repair at all...so we are eating it

& it is really a FANTASTIC cheese!!!!! unaged!

& it is really a FANTASTIC cheese!!!!! unaged!

Here is the other cheese from the tommee that I believe could not be pressed even though I put 40 pounds of weights on it....it is still very much broken, so we are eating it & did you know it is YUMMMMMYYY!!!!!

I STARTED all over & made a NEW ASIAGO with my newly found information. Here it is after being in the brine. I have two perfect cheeses from this new batch! The parts that I changed is, I pressed this at 20 pounds pressure right off the bat & pressed this for one hour & flipped. I pressed this for 10 hours. I then made a fresh brine of salt & water. I brined this for 6 hours. This cheese is as perfect as the last one was ruined!

This is my new little aging fridge. It is a small wine cooler. It says it will hold 8 wine bottles. I have three cheeses in it. The temperature control is perfect for aging cheese & with two bowls of water in it I have 80 percent humidity.

RSS Feed

RSS Feed