Gruyere is a cows milk cheese, having a French name. This is a Swiss version. Sometimes Gruyere has holes or eyes, it is a classic fondue cheese, with a nutty flavor that gets sweeter the longer it is aged. Suggested aging 2 months to 2 years.

Here are all my supplies. I have sanitized everything and laid them on a clean towel. I did forget to put the salt on this for the picture...so just imagine I have a box of salt in this picture. Notice...I am using store bought milk!

Warm the milk to 90 deg. I am a rebel, at heart....did you know that h ah aha h!!! I will tell you why....

The book suggested that I heat the milk in a water bath...but I wanted to heat it on the burner on low....I did & then I had a heck of a time getting it in the water bath with out slopping it!

The book suggested that I heat the milk in a water bath...but I wanted to heat it on the burner on low....I did & then I had a heck of a time getting it in the water bath with out slopping it!

I added Thermo C powdered starter culture.

I am sprinkling the culture on top and Let this rehydrate for a few minutes.

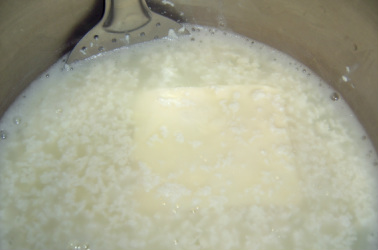

Here is a picture of me stirring the milk. I love it when still pictures can show movement. Stir this in an up and down motion Keep this temp for 30 min to let it ripen.

I now add calcium chloride diluted in water. Stir for one minute. I need this as I am using store bought milk that has been homogenized. With out this, the cheese would not turn out.

Now I am adding the rennet diluted in water. Stirring for one minute. Cover and let sit for 30-40 minutes or until curd gives a clean break.

This is after I cut the curd. This cheese really did not give a clean break even after 40 minutes. I think it is the store bought milk I used. I will be looking for another brand that hopefully will allow me to make a correct cheese.

This is after I let it sit 5 minutes. You can see the curds are starting to shrink. We will not be not stirring this until we have heated the curds up to 120 deg for 1 hour.

This is about 30 minutes into it. The curds have really shrunk.

This is after an hour. I gave it a stir and the curds were suppose to be firm & stretchy & instead they broke up to pieces! I was horrified....it is the store bought milk. Some other cheese people have told me they have had the same trouble & I will be searching for other brands of milk.

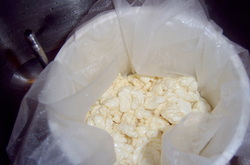

This is what the mess looked like. I talked to other Ian...a cheese friend of mine. He suggested I keep making the cheese and it will all work out in the end. You stir this for 15 minutes, then let it set for 20 so the curds can sink. I was upset enough about this not turning out I forgot to let it set for 20 min....oh, well...ha hahah

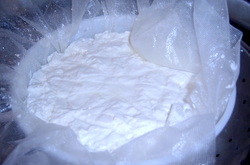

I put this in a cheese cloth lined tomme mould.

Press for one hour at 8 pounds. I am using the milk jug as it is 8 pounds nearly full of water.

I press this in the pot covered in a towel to help keep extra moisture in.

Flip & redress. Press at 10 pounds pressure for 12 hours. THAT would have been 3am! So I let it press till 5:30 am. I should have redressed it one more time in the middle of the night & next time I will do that...so there are no marks from the cheese cloth.

Here it is...

In a simple brine for 12 hours, flipping once.

Let this air dry covered loosely with a flour sack towel. Air dry for 8 hours until this is dry to the touch, flipping once. Then put this in a ripening box covered loosely. Flip daily for one week. Then you can choose to have a natural rind, brushing off mold once a week with a brush or clean the rind with a simple brine solution twice a week. I think will be cleaning with a brine solution twice a week.

RSS Feed

RSS Feed